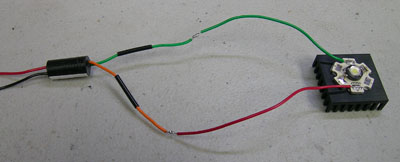

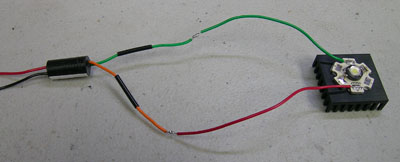

Here I've soldered the wires from the LED to the

driver. It's important to make sure the + and - connections are

hooked up properly as the LED will not light up if you hook it up

backwards.

By putting heat shrink tubing on the wires before

soldering them, I can just slide the heat shrink over the solder joint

and then heat it (I used a lighter) to make sure the wires don't touch

and short out. I like heat shrink tubing the best, but you can

use electrical tape as well. If using heat shrink, make sure to

shove it a ways away from the wire ends before soldering or else the

heat from the soldering iron will shrink it before you're ready.

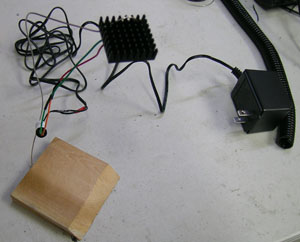

Here's a cheap "wall-wart" type power supply I'm

using. It's rated for 12V at 200mA or 2.4Watts. My LED will

only be using around 1W, so this supply should be fine. I've cut

the end off because I don't have the mating connector handy. I

plugged it into the wall and used my multimeter to determine which wire

was + and which was -. I put some red electrical tape on the +

wire so I could easily tell them apart.

Once I identified which wire from the power supply was +,

I soldered the two wires to the input of the bucktoot driver.

Again, it's important to make sure the polarity is correct before

applying power. Hooking things up backwards could damage the

power supply, driver, or LED.

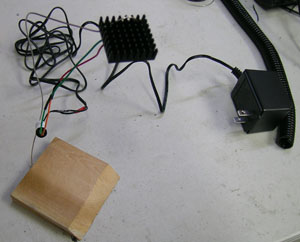

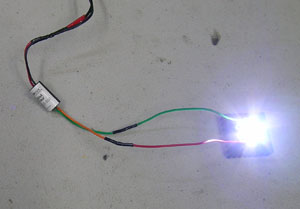

Here is the completed electrical system. The

wallwart plugs into the wall and sends power to the bucktoot

driver. The driver converts that power to way the LED likes it,

and then sends it on to the LED. The next step is to hook it up

and make sure it works!

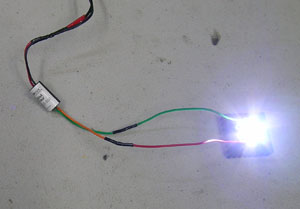

Yay! It works! These LEDs are bright!

After waiting for the spots in my vision to go away, it's time to put

the whole thing together.

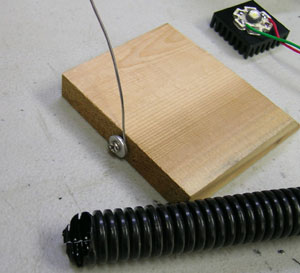

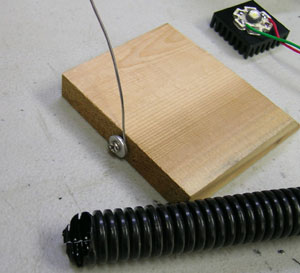

Here are all the parts for my desk lamp. I have the

power supply, driver, and LED w/ heat sink from before. Also in

the picture are a block of wood with some mechanic's wire (a stiff but

repositionable steel wire) screwed to it and some split-loom style

tubing.

To attach the mechanics wire to the wooden base, I just

bent the wire around the screw using my needle-nosed pliers and then

screwed the screw into the base. I added a washer to help pinch

the wire against the wooden base and keep it from turning.

After drilling a couple of holes in the heatsink, I bent

the mechanic's wire through the holes in such a way that it holds the

heat sink. It's a bit difficult to see in this picture, but the

heatsink and LED are about 8" in the air over the base. You can

see the bucktoot driver hanging in the air from the wires. We'll

hide that in just a moment.

I've hidden the colored wires, the mechanic's wire and the

driver inside the split-loom tubing. My lamp is complete.

After plugging it in, I immediately start using the

lamp. It's awesome! It's a lot brighter than my camera

makes it look, and it makes it really easy to read those tiny numbers

on electronic components or to identify resistor color bands. My

camera makes it look a little blue, but its actually a very nice white

and it does a much better job with the resistor color bands than the

overhead fluorescent lights I have in my lab.

This is an LED driver called a Bucktoot made by

LEDdynamics. The neat part about this driver is its small

size. It's only 3/4" long! The driver runs the LED with a

constant current (350mA). Because most electronics run with a

constant voltage instead of constant current, it is much easier to get

a constant voltage power supply. The driver converts the constant

voltage from the power supply into the constant current that the LED

needs to run properly.

This is an LED driver called a Bucktoot made by

LEDdynamics. The neat part about this driver is its small

size. It's only 3/4" long! The driver runs the LED with a

constant current (350mA). Because most electronics run with a

constant voltage instead of constant current, it is much easier to get

a constant voltage power supply. The driver converts the constant

voltage from the power supply into the constant current that the LED

needs to run properly. Here I've soldered the wires from the LED to the

driver. It's important to make sure the + and - connections are

hooked up properly as the LED will not light up if you hook it up

backwards.

Here I've soldered the wires from the LED to the

driver. It's important to make sure the + and - connections are

hooked up properly as the LED will not light up if you hook it up

backwards. By putting heat shrink tubing on the wires before

soldering them, I can just slide the heat shrink over the solder joint

and then heat it (I used a lighter) to make sure the wires don't touch

and short out. I like heat shrink tubing the best, but you can

use electrical tape as well. If using heat shrink, make sure to

shove it a ways away from the wire ends before soldering or else the

heat from the soldering iron will shrink it before you're ready.

By putting heat shrink tubing on the wires before

soldering them, I can just slide the heat shrink over the solder joint

and then heat it (I used a lighter) to make sure the wires don't touch

and short out. I like heat shrink tubing the best, but you can

use electrical tape as well. If using heat shrink, make sure to

shove it a ways away from the wire ends before soldering or else the

heat from the soldering iron will shrink it before you're ready.

Here's a cheap "wall-wart" type power supply I'm

using. It's rated for 12V at 200mA or 2.4Watts. My LED will

only be using around 1W, so this supply should be fine. I've cut

the end off because I don't have the mating connector handy. I

plugged it into the wall and used my multimeter to determine which wire

was + and which was -. I put some red electrical tape on the +

wire so I could easily tell them apart.

Here's a cheap "wall-wart" type power supply I'm

using. It's rated for 12V at 200mA or 2.4Watts. My LED will

only be using around 1W, so this supply should be fine. I've cut

the end off because I don't have the mating connector handy. I

plugged it into the wall and used my multimeter to determine which wire

was + and which was -. I put some red electrical tape on the +

wire so I could easily tell them apart. Once I identified which wire from the power supply was +,

I soldered the two wires to the input of the bucktoot driver.

Again, it's important to make sure the polarity is correct before

applying power. Hooking things up backwards could damage the

power supply, driver, or LED.

Once I identified which wire from the power supply was +,

I soldered the two wires to the input of the bucktoot driver.

Again, it's important to make sure the polarity is correct before

applying power. Hooking things up backwards could damage the

power supply, driver, or LED. Here is the completed electrical system. The

wallwart plugs into the wall and sends power to the bucktoot

driver. The driver converts that power to way the LED likes it,

and then sends it on to the LED. The next step is to hook it up

and make sure it works!

Here is the completed electrical system. The

wallwart plugs into the wall and sends power to the bucktoot

driver. The driver converts that power to way the LED likes it,

and then sends it on to the LED. The next step is to hook it up

and make sure it works! Yay! It works! These LEDs are bright!

After waiting for the spots in my vision to go away, it's time to put

the whole thing together.

Yay! It works! These LEDs are bright!

After waiting for the spots in my vision to go away, it's time to put

the whole thing together. Here are all the parts for my desk lamp. I have the

power supply, driver, and LED w/ heat sink from before. Also in

the picture are a block of wood with some mechanic's wire (a stiff but

repositionable steel wire) screwed to it and some split-loom style

tubing.

Here are all the parts for my desk lamp. I have the

power supply, driver, and LED w/ heat sink from before. Also in

the picture are a block of wood with some mechanic's wire (a stiff but

repositionable steel wire) screwed to it and some split-loom style

tubing. To attach the mechanics wire to the wooden base, I just

bent the wire around the screw using my needle-nosed pliers and then

screwed the screw into the base. I added a washer to help pinch

the wire against the wooden base and keep it from turning.

To attach the mechanics wire to the wooden base, I just

bent the wire around the screw using my needle-nosed pliers and then

screwed the screw into the base. I added a washer to help pinch

the wire against the wooden base and keep it from turning. After drilling a couple of holes in the heatsink, I bent

the mechanic's wire through the holes in such a way that it holds the

heat sink. It's a bit difficult to see in this picture, but the

heatsink and LED are about 8" in the air over the base. You can

see the bucktoot driver hanging in the air from the wires. We'll

hide that in just a moment.

After drilling a couple of holes in the heatsink, I bent

the mechanic's wire through the holes in such a way that it holds the

heat sink. It's a bit difficult to see in this picture, but the

heatsink and LED are about 8" in the air over the base. You can

see the bucktoot driver hanging in the air from the wires. We'll

hide that in just a moment. I've hidden the colored wires, the mechanic's wire and the

driver inside the split-loom tubing. My lamp is complete.

I've hidden the colored wires, the mechanic's wire and the

driver inside the split-loom tubing. My lamp is complete. After plugging it in, I immediately start using the

lamp. It's awesome! It's a lot brighter than my camera

makes it look, and it makes it really easy to read those tiny numbers

on electronic components or to identify resistor color bands. My

camera makes it look a little blue, but its actually a very nice white

and it does a much better job with the resistor color bands than the

overhead fluorescent lights I have in my lab.

After plugging it in, I immediately start using the

lamp. It's awesome! It's a lot brighter than my camera

makes it look, and it makes it really easy to read those tiny numbers

on electronic components or to identify resistor color bands. My

camera makes it look a little blue, but its actually a very nice white

and it does a much better job with the resistor color bands than the

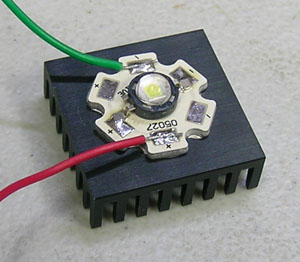

overhead fluorescent lights I have in my lab. Here I've mounted an LED Star to a heatsink. While

the 05027 Star usually carries a Luxeon K2 LED, here I've replaced it

with a Seoul P4 that I was able to get my hands on.

I put some red and green wires on the star and

then glued it to the heatsink using Arctic Silver thermal

adhesive (make sure you use the adhesive version of the Arctic Silver if

you want to glue the LED to the heat sink. Arctic Silver also makes a thermal grease,

but you would have to drill/tap the heat sink and use screws to attach the star if you

wanted to use that).

It is important to have a good thermal path between the

LED and the heat sink to keep the LED cool. This is because LEDs

get dimmer when they get too hot, and it can also shorten their

lifetime.

Here I've mounted an LED Star to a heatsink. While

the 05027 Star usually carries a Luxeon K2 LED, here I've replaced it

with a Seoul P4 that I was able to get my hands on.

I put some red and green wires on the star and

then glued it to the heatsink using Arctic Silver thermal

adhesive (make sure you use the adhesive version of the Arctic Silver if

you want to glue the LED to the heat sink. Arctic Silver also makes a thermal grease,

but you would have to drill/tap the heat sink and use screws to attach the star if you

wanted to use that).

It is important to have a good thermal path between the

LED and the heat sink to keep the LED cool. This is because LEDs

get dimmer when they get too hot, and it can also shorten their

lifetime.